USpharma transitioned from outsourcing strategy for commercial manufacturing to fully-integrated manufacturing platform.

Address: 13900 NW 57th Court, Miami Lakes, FL 33014

- Acquired a large-scale commercial operation in Miami Lakes, Florida from Merck.

- 150,000 sq ft manufacturing facility.

- Fully-secured three building campus, including office space, production, lab, training and warehouse space.

- Major infrastructure upgrades of $9 Million, including heavy power, HVAC, warehouse, cafeteria, and fire system.

- The facility provided unique value and opportunities, including:

- State-of-the-art, high-capacity manufacturing capabilities.

- Rights to key systems from Merck.

- Near-term product launch,.

- Access to the $4 billion niche generic transdermal market.

- Access to the large volume solid-dose and topical markets.

- FDA audit in 2017; Inspected by DEA in 2018

- Received DEA Schedule I Manufacturer License

Alwajer Pharmaceutical Co. LLC

Location: Sohar Industrial Area, Sultanate of Oman

Total Land Area: 15,000 sq. meters

Alwajer Pharma is the only company in the Middle East manufacturing Pharmaceutical Pellets. It has been developed to manufacture all kinds of pharmaceutical pellets with a current installed capacity of 20 MT per month. The company has future expansion plans to 35 MT per month in next 5 years. GMP certification for the facility is under process.

It has started its commercial productions from 2018.

Products:

- Pharmaceutical Pellets

- Pre-formulation Intermediates (PFI)

- Taste Masked Granules

- DC Granules

- Syrup Suspension Granules

Quality assurance during production and quality control is the key to the consistent production of highest quality specialty products. The company has a comprehensively designed and correctly implemented system of quality assurance incorporating current Good Manufacturing Practices, Quality Control and Quality Risk Management to achieve its quality objective reliably. Documentation, compliance, deviation reporting and corrective and preventive actions are practiced vigorously.

Separate premises for cephalosporins and general products which include different dosage forms having HVAC and ETP (Effluent Treatment Plant) facilities.. Maintaining proper documentation and utilizing modern production machinery and equipment different dosage forms like tablets, capsules, liquid filled capsules, powders, creams, ointment, lotion, oral liquids, injectables, ophthalmic preparations are manufactured in segregated areas to consistently produce products of highest quality. Well defined standard operating procedures (SOP) in compliance with the procedures and guidelines are followed and documented in batch manufacturing records incompliance with the cGMP.

General Production: Separate Premises with required facilities for Tablet, Capsule and Powder for suspension

Cephalosporins: Separate Premises with required facilities for Tablet, Capsule and Powder for suspension

Injectables: Large Volume Parenterals and Small Volume Parenteral

Ophthalmic Preparations

Development of branded generic products is given very high importance in the organization. Product Development Department is equipped with all required facilities and managed by a team of qualified personnel. They are responsible for designing formulation, developing manufacturing process and undertaking stability to develop products which meets high standards and consistent quality.

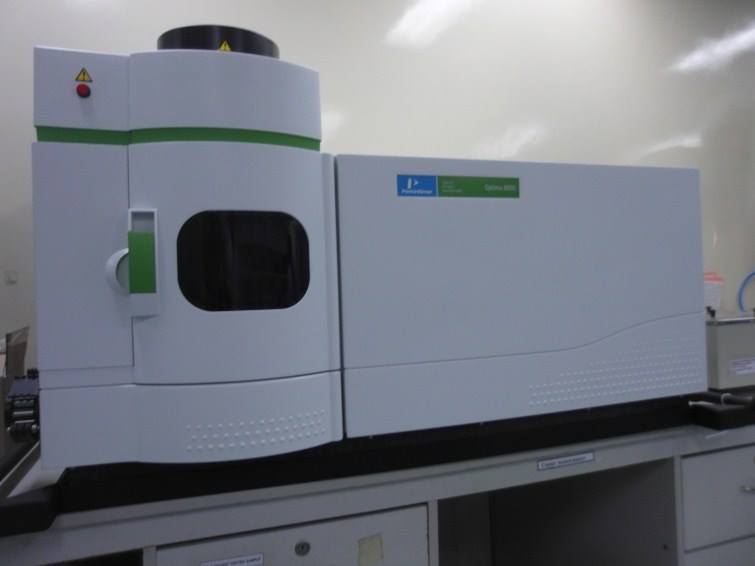

Producing products of highest quality have been possible with a well-equipped and well documented quality control laboratory. The quality control laboratory is equipped with all major instruments including Atomic Absorption Spectrophotometer, TOC analyzer, FTIR, UV- Visible Spectrophotometer, Binary & Quaternary HPLC to analyze all aspects of products quality and ensure regulatory compliance. During tests and analysis, the Good Laboratory Practices are followed. Microbiology tests are also carried out in a dedicated microbiology laboratory